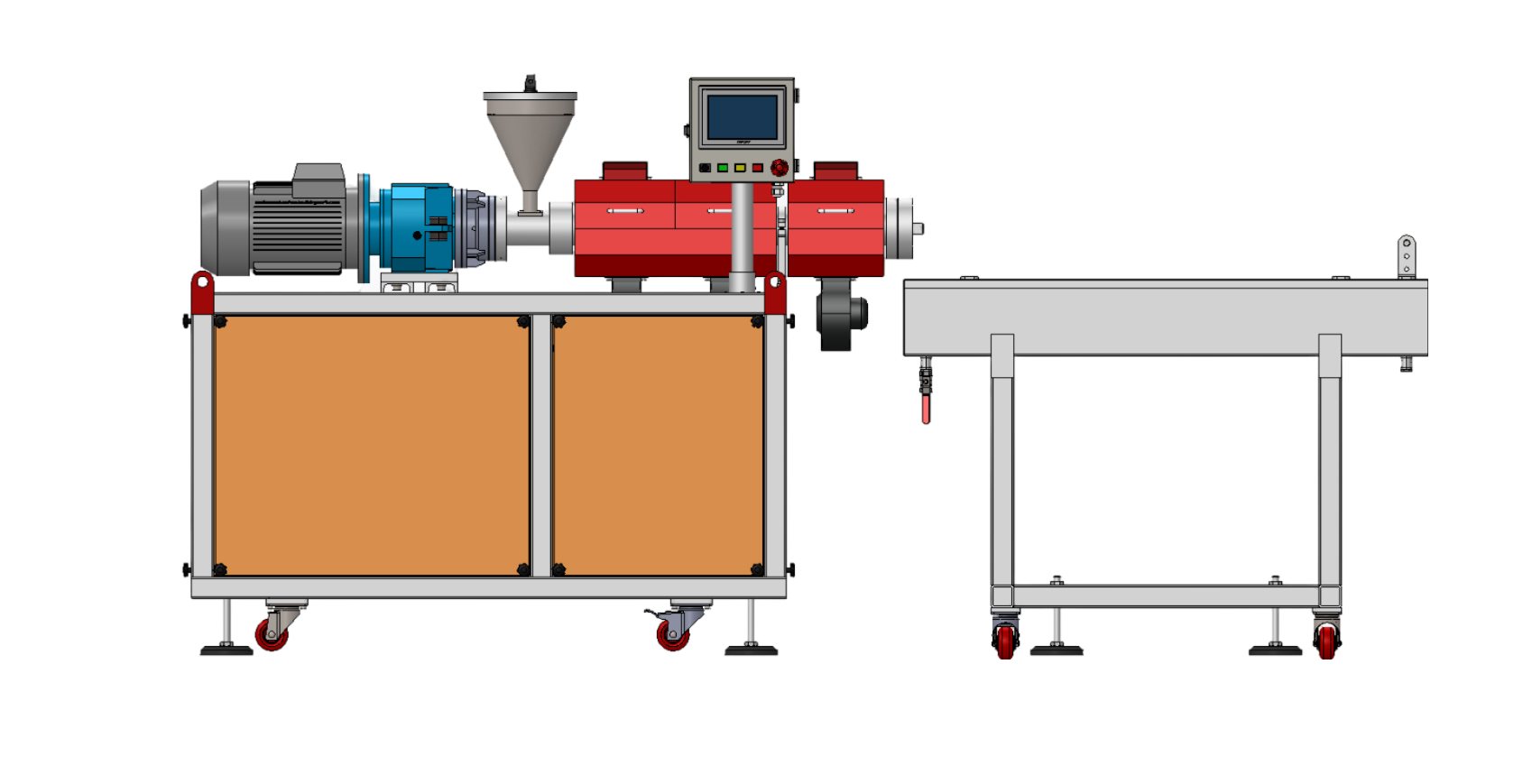

Laboratory extruder is specially designed for the trial-level or entry-level user, or the small scale production. Modular design makes it very flexible against different recipes.

| LAB GRANUAL PLANT | ||||

| MODEL | SCREW DIA | L/D | KW | THROUGHPUT KG/HR. |

| PEG-25 | 25 | 22 | 1.5 | 1 TO 3 |

| PEG-30 | 30 | 25 | 2.2 | 5 TO 8 |

| PEG-35 | 35 | 28 | 3.7 | 10 TO12 |

| PEG-45 | 45 | 30 | 5.5 | 20 TO 25 |

Also available in customized Sizes

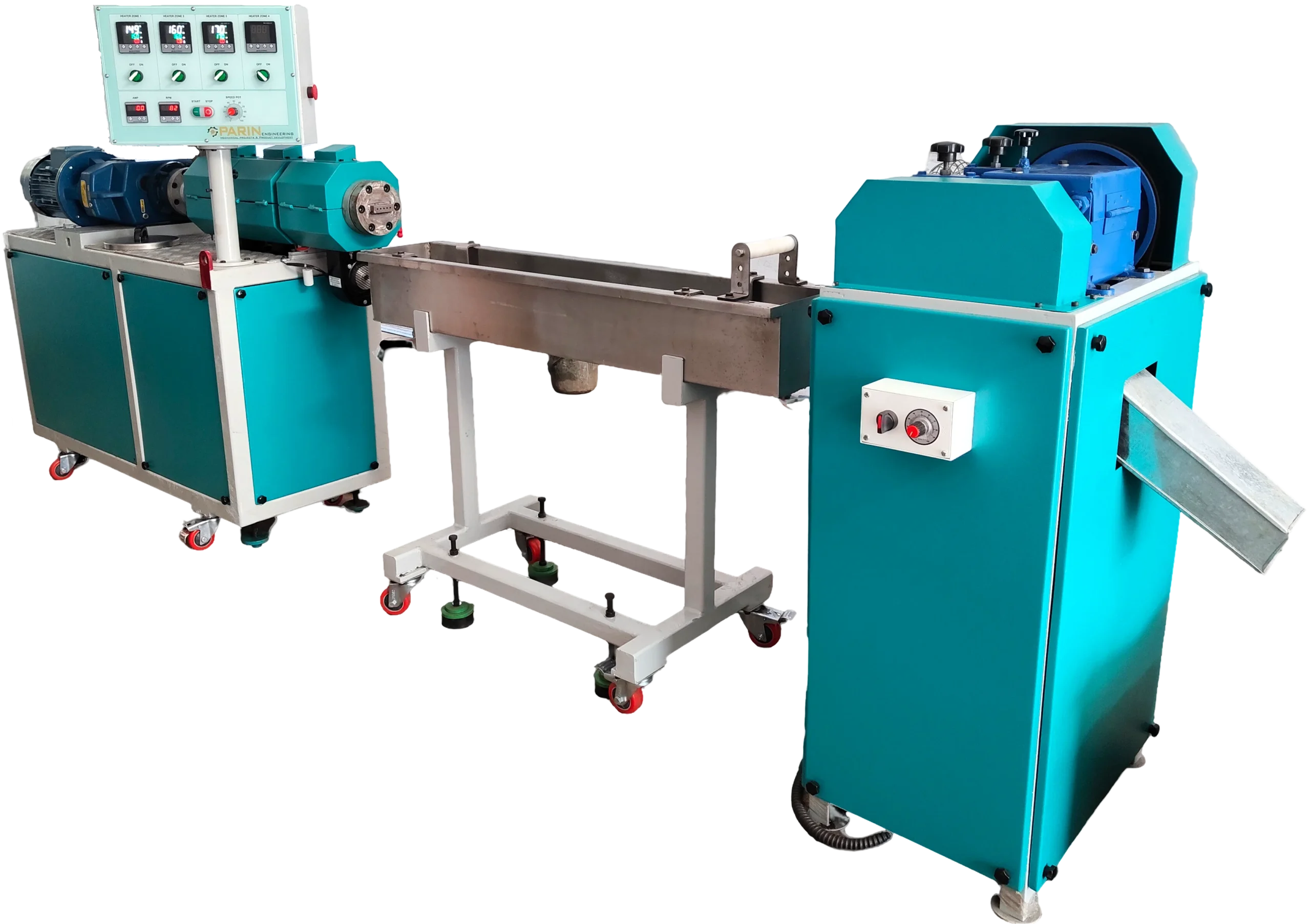

The machine was specifically designed and crafted for laboratory purposes and small-scale industries for production. It is easy to operate, offers trouble-free performance, requires low maintenance, occupies minimal working space, and is easy to transfer—all excellent features that elevate the machine to the premium category.

Our Lab Extrusion Machine is utilized in various government laboratories, granule production manufacturing industries, sheet manufacturing sectors, compounding or testing facilities, small-scale production industries, and more. We offer a range of models, as shown below, to meet customer requirements. Additionally, we provide customized machines tailored to specific needs. We are also manufacturers of Lab model Extrusion machine parts, suppliers of spares, and service providers.

Our compact lab extruders combine mechanical and electrical components, adhering to the plug-in concept.

To facilitate data acquisition, we utilized various sensors alongside machines and focused on enhancing the interface and I/O design for future scalability. You have a wide range of screw geometries and screw speeds.

Control systems can be located both on-site and off-site. Our experts can diagnose your machines through the internet module. From button panels to industrial computers, we can tailor a control system to meet your specific requirements and budget.

We have invented, designed, developed and engineered a wide variety of successful products including consumer products Road Construction equipments, Plastic Machineries, Pipe Coating Industries, Custom Machine Design & developments.

Copyright © 2026 – Product Gallery | About Us | Contact Us