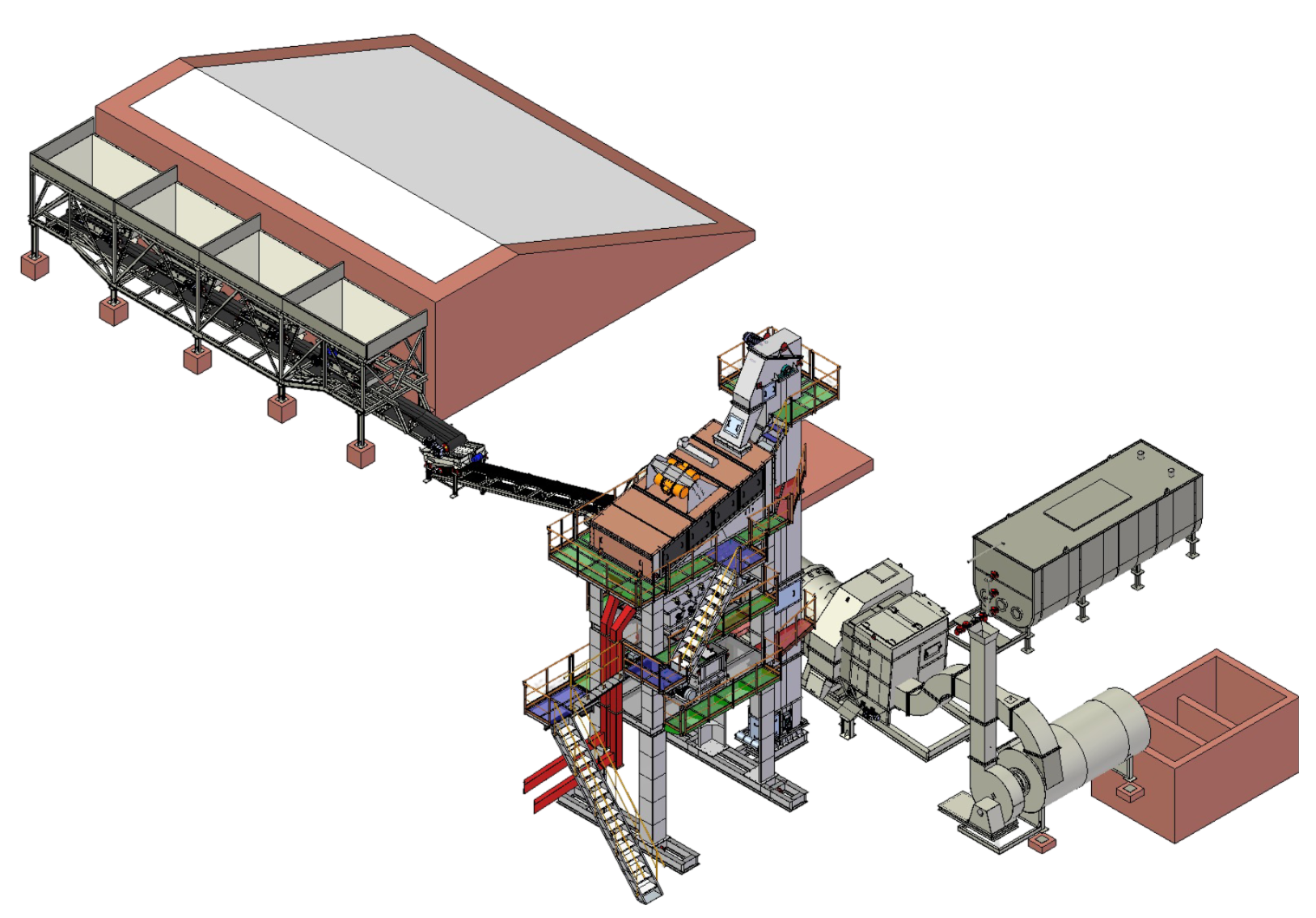

We have created our tower unit with extreme attention to details so that the various components of the system work together to ensure a seamless performance. We have kept the design perfectly free floating so that the vibrations do not affect the performance of the system in any way. We have also introduced multiple inspection doors that make it easier for the working team to carry out inspections as and when they want. The pneumatic controls that come with the hot bin unit make it easier to implement effective input control for the aggregates, which can become crucial during various projects.

The advantage for customers here is that they get the benefit of both the plants without compromising on the overall productivity. Ideally 40-60 tph Drum mix asphalt plant can be paired with a 80 tph Batch mix plant, 60-90 tph asphalt drum mixing plant can be paired with 100 tph Batch mix plant & 90-120 tph drum mixing hot mix plant can be paired with 120 tph Batch mix plant.

Batch mixing plants create asphalt in discrete batches, providing precise control over the composition of the mix. In contrast, drum mix plants continuously mix the asphalt components, offering a more streamlined production process. Each type has its distinct advantages and is suited to different project needs.

The operation of an asphalt batch mix plant begins by feeding the aggregates into the feeder containers. When hot mixed asphalt is discharged into the truck, the operation of the asphalt batch mix plant concludes.

We have invented, designed, developed and engineered a wide variety of successful products including consumer products Road Construction equipments, Plastic Machineries, Pipe Coating Industries, Custom Machine Design & developments.

Copyright © 2025 – Product Gallery | About Us | Contact Us