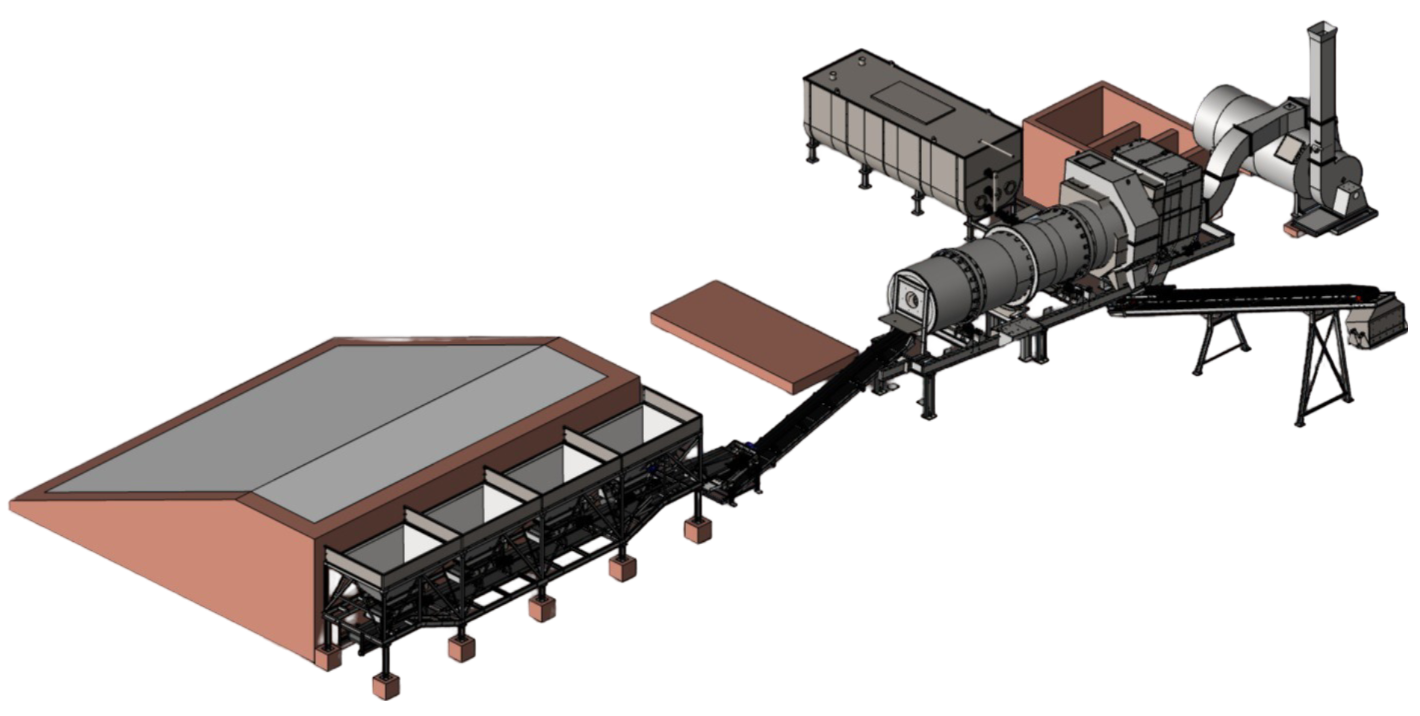

Asphalt Drummix Plant is designed to offer customers worldwide a lower capital-cost modular asphalt drum plant while maintaining many capacity range features.

This has benefited customers in numerous ways, leading to strong support for our products in the past and ongoing trust in our machines due to their consistent top quality. As a skilled drum mix plant manufacturer, we ensure that the flight pattern of the drum is meticulously designed through years of research and development, allowing customers to enjoy the advantages of our design in their products.

The Hot Mix Plant process is a key part of producing the asphalt used in road construction. It begins with various types of rocks, including sand and gravel, stored in separate bins. These rocks are then heated and dried in a special oven, removing any moisture. Once dry, they’re mixed together with hot bitumen, a thick, sticky form of petroleum, in a large mixer. The heat ensures a strong bond between the rocks and the bitumen, creating a hot, adhesive mixture.

| MODEL | PEDM – 45 | PEDM – 50 | PEDM – 60 |

| PLANT CAPACITY (TPH)* | 45- 60 | 60 – 90 | 90 – 120 |

| DIMENSION OF THERMO DRUM UNIT (LXWXH) (m) | 10.60 X 2.50 X 2.70 | 11.80 X 2.70 X 2.80 | 13.90 X 2.90 X 3.10 |

| BURNER SIZE ( l/h) | 200 – 250 | 300 – 350 | 550 – 600 |

| BURNER TYPE | Hi – Lo Type Pressure Jet | Hi – Lo Type Pressure Jet | Hi – Lo Type Pressure Jet |

| FUEL TYPE | HSD, LDO | HSD, LDO | HSD, LDO |

| EXHAUSTER UNIT (CFM) | 10500 | 14500 | 15500 |

| DUST COLLECTOR | 15 Cones | 20 Cones | 24 Cones |

| DRUM DIAMETER (m) | 01.20 | 01.50 | 01.80 |

| FEEDER CAPACITY ( kg) | 32000 | 44000 | 44000 |

| BITUMEN TANK (CAPACITY IN LITER ) | 15000 / 20000 / 30000 | ||

| FILLER CAPACITY (kg) | 1000 | ||

| POWER REQUIRED TOTAL (KW) | 79 | 94.38 | 115.76 |

| TOTAL AREA REQUIRED FOR INSTALLATION | 35 X 35 m | 38 X 38 m | 45 X 45 m |

| GEAR DETAIL | |||

| AUXILIARY CONVEYOR | Helical Type | ||

| GATHERING CONVEYOR | Helical Type | ||

| SLINGER CONVEYOR | Helical Type | ||

| LOADOUT CONVEYOR | Helical Type | ||

| SCREW CONVEYOR | NU Worm Type | ||

| DRUM DRIVE UNIT | SNU Worm Type | ||

| BITUMEN PUMP | Gear Type | ||

| 3% moisture content in cold aggregates, 38OC atmospheric temprature, aggregated density of 1.6 tons /m3, mean sea level, | |||

A drum mix plant producing asphalt will do so in its different method. It will have its own advantages and features when compared with any other type. One of the top benefits will include its easy operation, maintenance and low initial cost of investment. A drum plant is always preferred for its ability to quickly produce hot mix asphalt in short period of time.

We have invented, designed, developed and engineered a wide variety of successful products including consumer products Road Construction equipments, Plastic Machineries, Pipe Coating Industries, Custom Machine Design & developments.

Copyright © 2026 – Product Gallery | About Us | Contact Us