Parin Engineering is a well-known manufacturer of PU Foam & Internal and External Powder (FBE) Epoxy Pipe Conveying Plants.

Solid PU pipe coatings are primarily applied to protect the interior surfaces of pipelines transporting water or abrasive media. PU foam pipe coating on the exterior of pipelines is added for thermal insulation purposes. Bauhaus has supplied several pipe coating plants for the application of both types of coatings. For applying the foam on the exterior, Bauhaus offers various solutions, such as a continuous system with a helical pipe conveyor or a discontinuous system using a pipe coating buggy. In the latter case, the pipe is positioned with the outer ends on a traveling pipe rotation unit and passes a stationary spray gun. PU pipe coating plants come equipped with all necessary PU pipe coating equipment, including a tank farm, temperature-controlled day tanks, dosing equipment for adding blowing agents, and a main mix pump with spray guns, all supplied by renowned manufacturers.

Pre-insulated pipe system consisting of thermally efficient polyurethane (PUR) or polyisocyanurate (PIR) insulation, a waterproof fiberglass-reinforced polymer (FRP) outer jacket, and a service pipe to meet challenging project requirements.

Steel pipe foam insulation equipment is utilized to apply an insulation layer and an anti-corrosion layer to the external surface of steel pipes, creating a thermal insulation layer. It offers several advantages, including continuous operation, high production efficiency, low cost, energy savings, and no pollution.

On site PUF insualtion is done by using low pressure dispenser machine and spray gun.

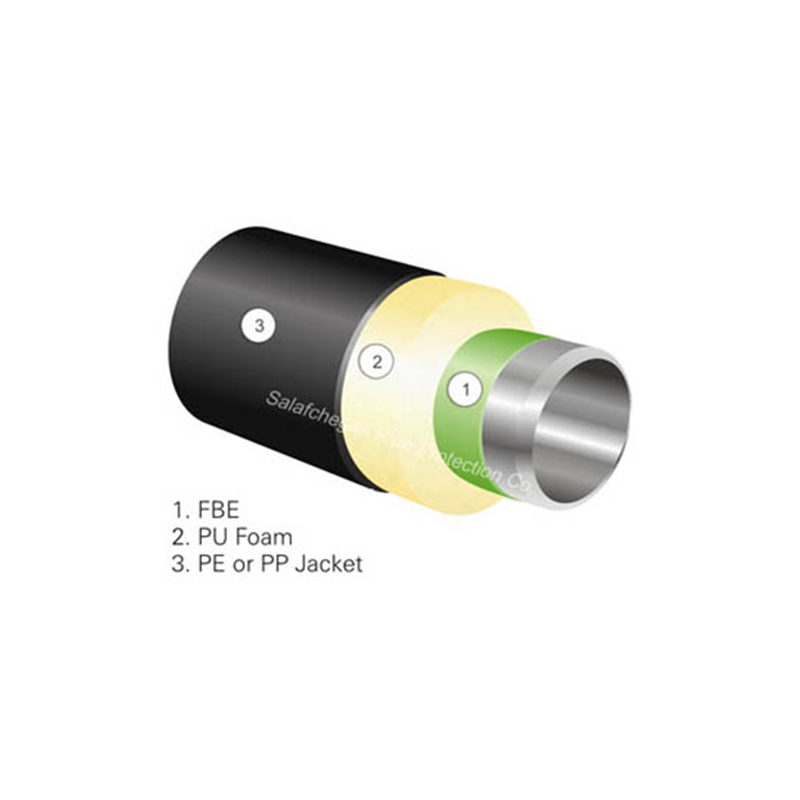

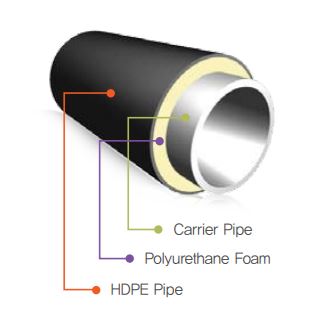

These pipes are made by combining seamless steel pipes with high-density polyurethane foam insulation and an outer protective jacket. PUF pre-insulated pipes are designed to transport hot and cold liquids and gases while maintaining a consistent temperature throughout the pipeline, making them ideal for various industrial and commercial applications.

The PU pipe coating (polyurethanes pipe coating) is either sprayed onto the pipe surface with the pipe ends placed on rotation units or onto the pipe travelling passed the airless spray gun on a helical pipe conveyor. The last type of application requires a very fast curing PU as before the pipe hits the first conveyor wheel after application the pipe coating must be able to carry the weight of the pipe.

For the application of PU foam coating Bauhuis offers various PU Foam pipe coating equipment like tilting tables whereby the pipe is first inserted into a jacket with spacers present between the jacket and the steel pipe. Then the pipe is placed on a tilting table and foam is injected from the top in between the jacket and the pipe.

Reduce or prevent equipment damage resulting from fire-stop systems

We have invented, designed, developed and engineered a wide variety of successful products including consumer products Road Construction equipments, Plastic Machineries, Pipe Coating Industries, Custom Machine Design & developments.

Copyright © 2026 – Product Gallery | About Us | Contact Us